Bearing production process

- Time of issue:2021/11/27

(Summary description)ball bearing production process

Bearing production process

(Summary description)ball bearing production process

- Categories:Blog

- Author:Andy Dong

- Origin:

- Time of issue:2021-11-27 14:39

- Views:

Bearing production process

The specific production process of the bearing: raw materials-inner and outer ring processing, steel ball processing, cage processing-bearing assembly-bearing finished product.

In the bearing production process, the most critical are the following links:

1. Forging link

The forging link is an important link to ensure the reliability and life of the bearing. After the raw material is forged, the bearing ring blank is formed. At the same time, the organization structure of the raw materials becomes denser and the flow linearity becomes better, which can improve the reliability and service life of the bearing. In addition, the quality of the forging process will directly affect the utilization rate of raw materials, thereby affecting production costs.

2. Heat treatment link

The heat treatment process is to subject the forged and machined bearing ring to high temperature treatment, which directly affects the uniformity of carburization in the bearing ring, improves the wear resistance and hardness of the bearing, and also affects the reliability and life of the bearing. Important link

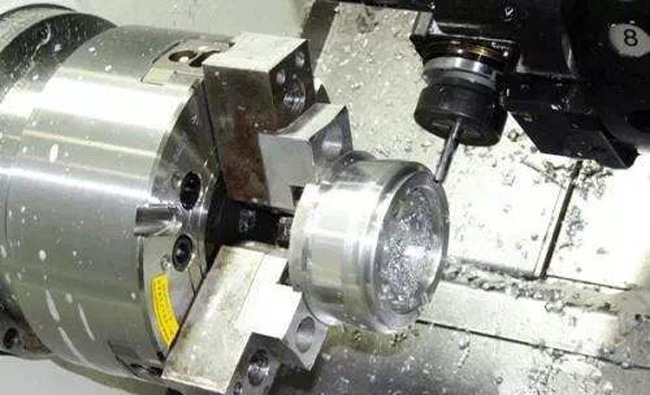

3. Grinding and processing links

After the heat treatment, the bearing ring needs to be ground, which is an important link to ensure the accuracy of the bearing. After grinding, the production process of the bearing ring is basically completed.

Process flow of bearing inner and outer rings: bar material-forging-turning-heat treatment-grinding-super finishing-final inspection of parts-rust prevention storage.

Rolling bearing parts such as inner ring, outer ring, rolling element and cage, etc., after passing the inspection, enter the assembly workshop for assembly. The process is as follows:

Parts demagnetization, cleaning→internal and external rolling <groove> channel size grouping selection→fitting→check clearance→riveting cage→final inspection→demagnetization, cleaning→rust prevention, packaging→into the finished product warehouse (packing, shipping 〉.

Scan the QR code to read on your phone

Relevant news

TOP

Covince yourself of our HT products !

© 2021 Hongtai All Rights Reserved. | 浙ICP备05089906号-1 | Powered by www.300.cn

Follow us