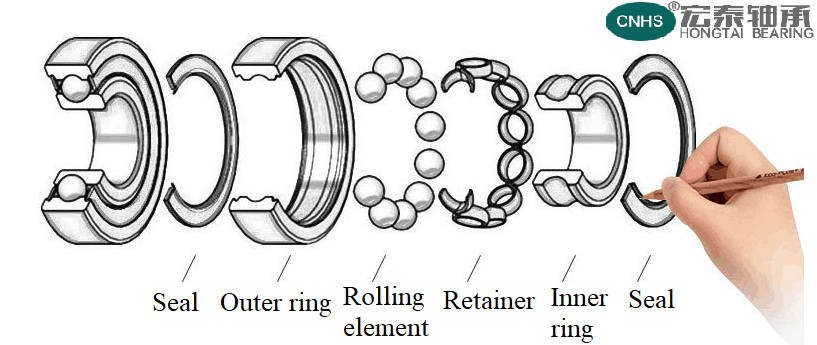

The composition of deep groove ball bearings

Date:

Oct 21,2021

The composition of deep groove ball bearings

Details:

Deep groove ball bearings (GB/T 276—2003) originally listed radial ball bearings are the most widely used rolling bearing.

It is characterized by low frictional resistance and high speed.

It can be used on parts that bear radial load or a combined load that acts on both radial and axial directions.

It can also be used on parts that bear axial load, such as low-power motors, Automobile and tractor gearboxes, machine tool gearboxes, general machines, tools, etc.

Deep groove ball bearing is the most common type of rolling bearing.

It consists of an outer ring, an inner ring, a group of steel balls and a group of retainer structures.

Due to the different working conditions, there will be a distinction between open and sealed bearings in the formal use process.

Deep groove ball bearings have a simple structure and are easier to achieve higher manufacturing accuracy than other types.

Therefore, they are easy to produce in series and have lower manufacturing costs, and they are extremely common.

In addition to the basic type, deep groove ball bearings also have various modified structures, such as:

Deep groove ball bearings with dust cover, the industry term is called ZZ

Deep groove ball bearings with rubber seals, the industry term is called RS

Deep groove ball bearings with snap grooves, the industry term is called NER

Deep groove ball bearing with large load capacity with ball gap, and double row deep groove ball bearing.

Relevant news

How to use the PN# to find the correct bearing in CNNBHT

Learn moreWith the end of the COVID-19 pandemic, things are starting to work normally.

Learn more

![[Exhibition Announcement]Hongtai Bearing-PTC ASIA 2025 E8-A2-1 [Exhibition Announcement]Hongtai Bearing-PTC ASIA 2025 E8-A2-1](https://omo-oss-image.thefastimg.com/portal-saas/pg2024090417521609331/cms/image/8dce34b2-b35e-45d2-913e-a8697dafcbe3.webp)